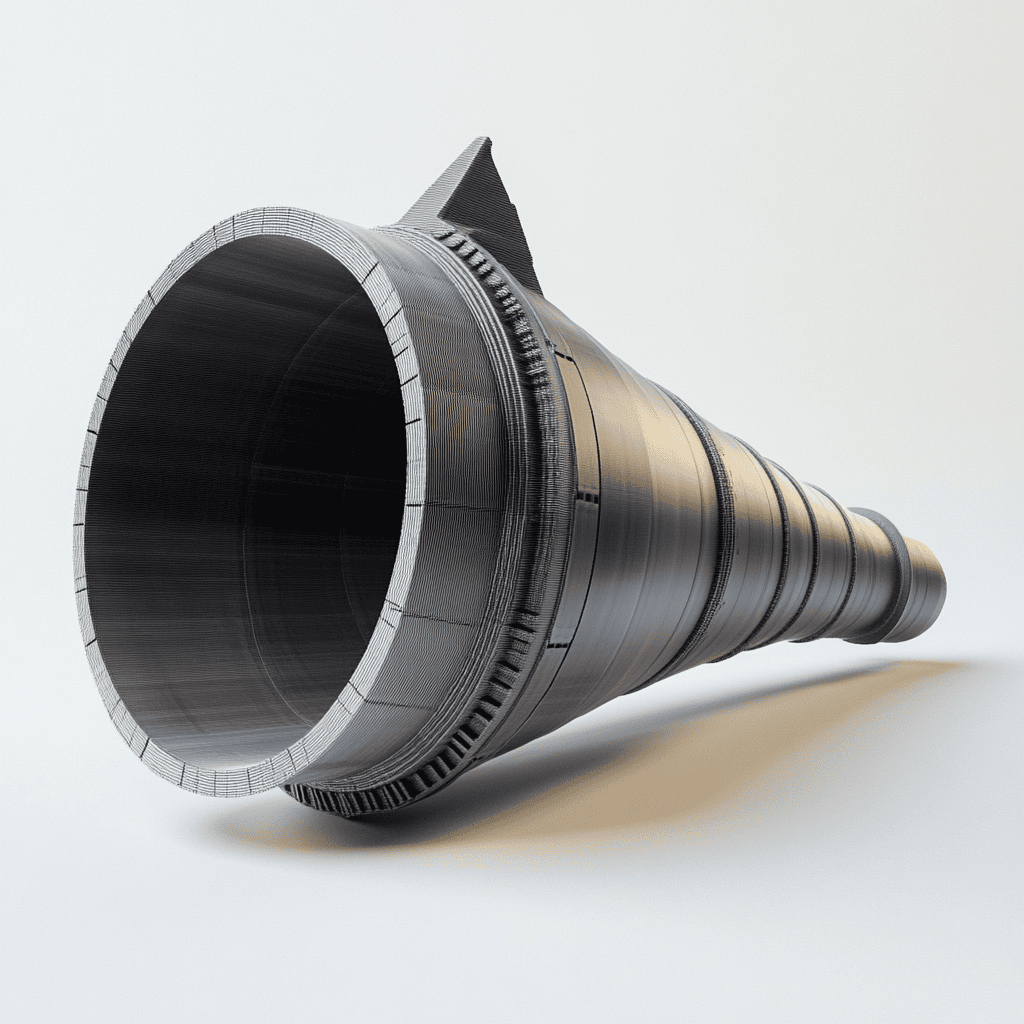

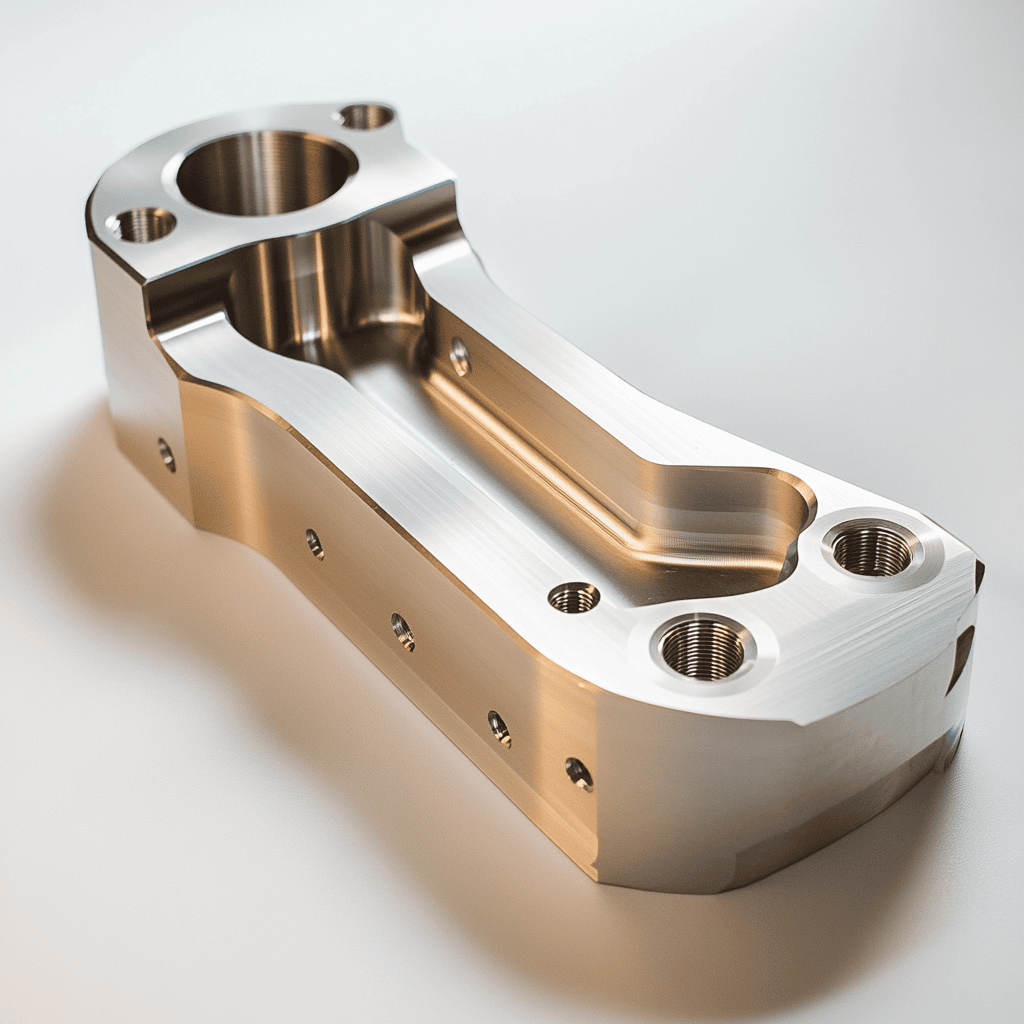

Trustbridge provides fast, flexible urethane and silicone casting services through our global network of certified partners. Whether you’re building short-run prototypes, marketing samples, or low-volume production parts, our platform connects your project to the ideal casting partner — matched by material, tolerances, timeline, and finishing needs.

With in-house engineering support and access to advanced vacuum casting, RTV molding, and pressure casting techniques, we help you bridge the gap between prototyping and injection molding. Get production-quality parts without the tooling investment.

Frequently Asked Questions

What’s the difference between urethane and silicone casting?

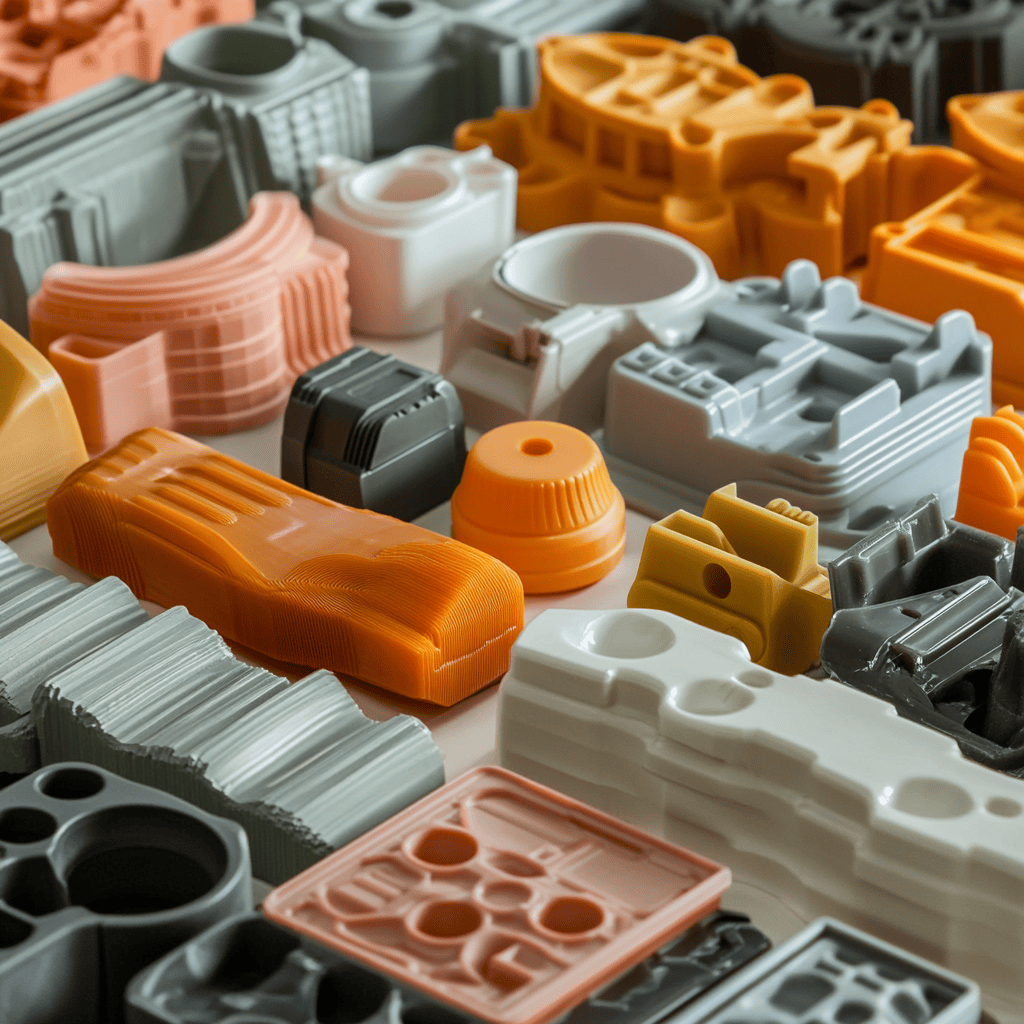

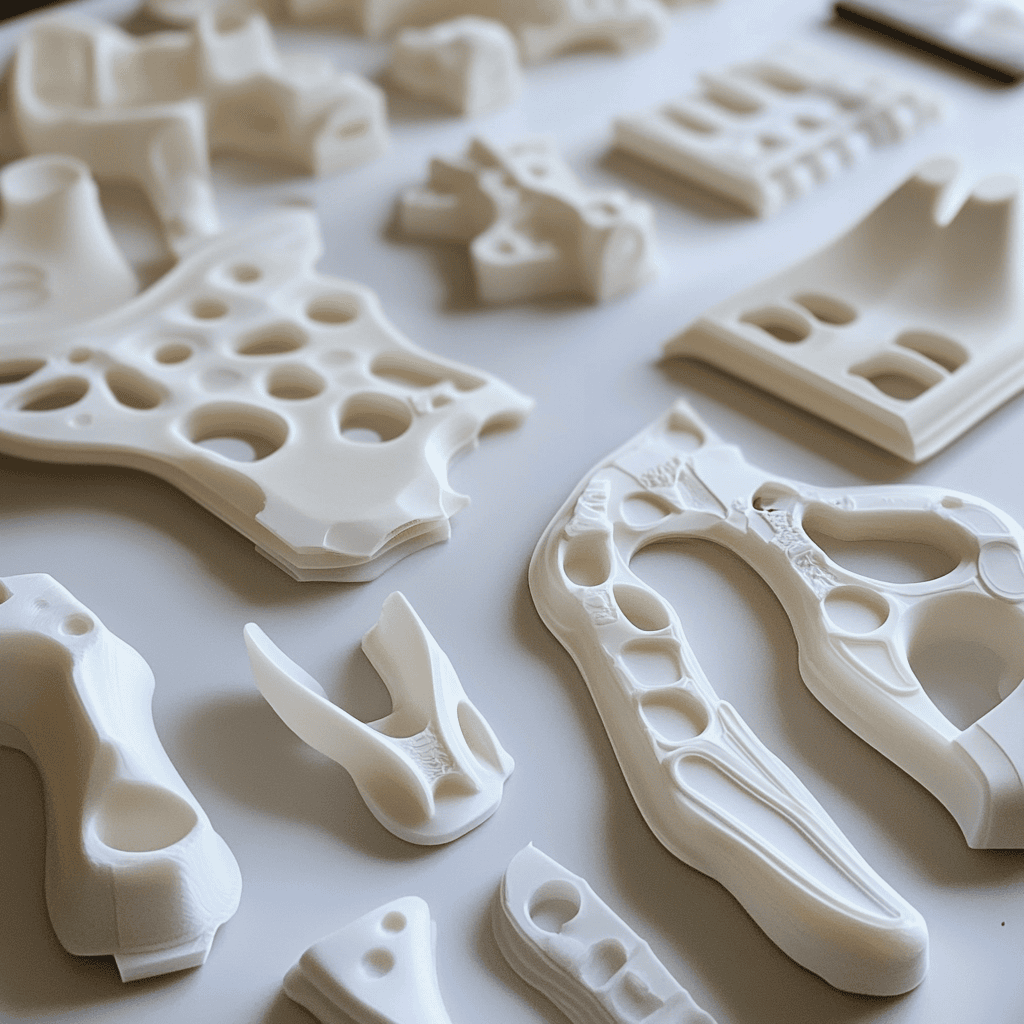

Urethane casting is used for rigid and flexible plastic-like parts. Silicone casting is ideal for rubbery, soft, or heat-resistant parts.

Can I get clear or tinted parts?

Yes — we offer water-clear urethanes and pigmented resins in custom or Pantone-matched colors.

How many parts can be made per mold?

Typically 20–25 shots per mold, depending on geometry and resin chemistry.

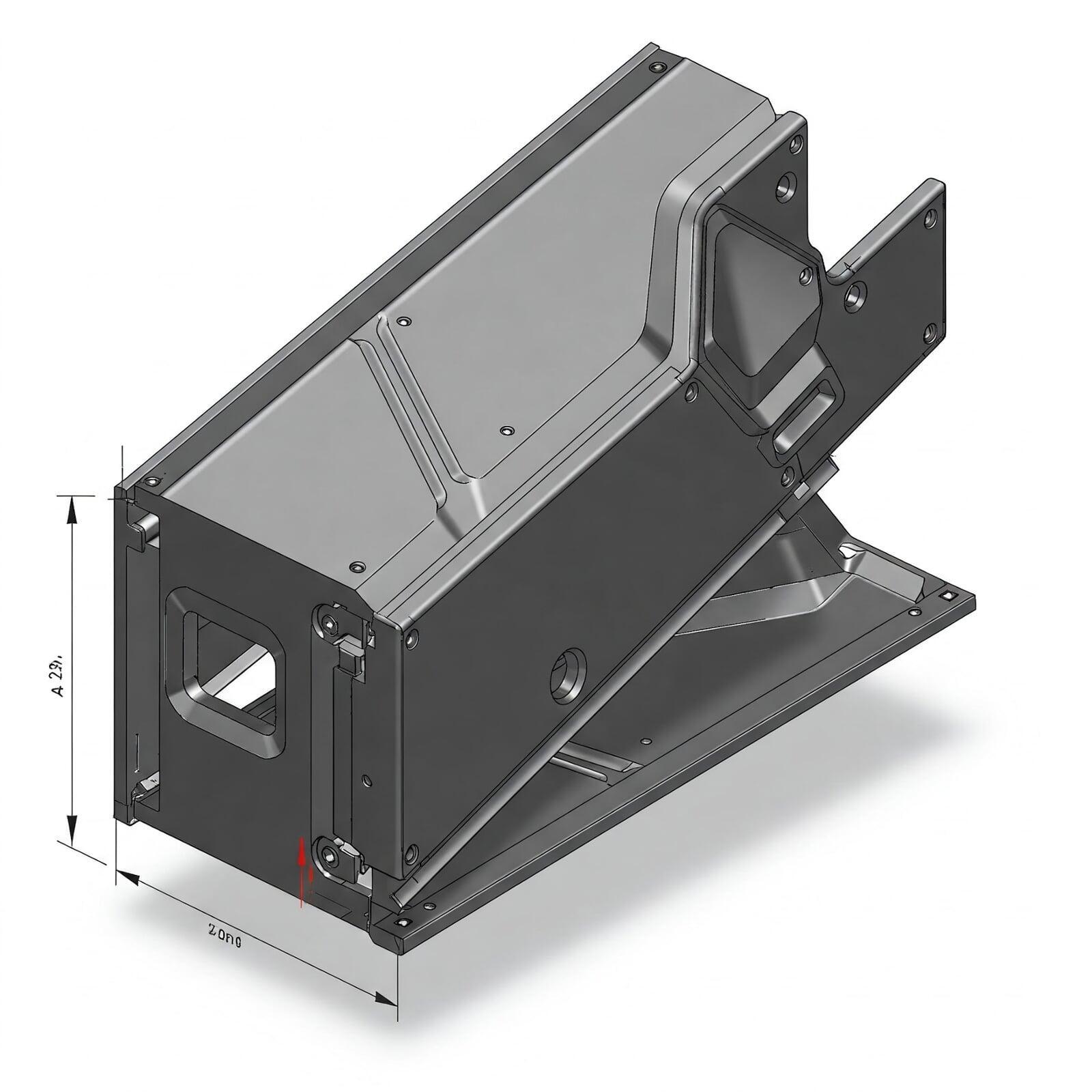

What file types do you accept?

STEP, IGES, STL, and native CAD files for master pattern production.

Can you handle overmolding or dual-shot parts?

Yes — many partners offer soft-over-hard or two-material casting options.